Pandrol

Visiting address

Station Road 63

KT15 2AR

Addlestone

Postal address

Station Road 63

Addlestone , KT15 2AR

Contact person

Kerri MurrayJoin our community for FREE today!

Create and share your own profile

Join the discussions

Publish your own items

Subscription to our Weekly eNewsletter

Get connected with Mass Transit Professionals Worldwide

FREE membership benefits

- * create and share your own profile

- * join the discussions

- * publish your own items on Mass Transit Networkmanage news, jobs, tenders, companies, events, showcases, educations, associations and literature.

- * subscribe to our eNewsletter

Company information

Pandrol has been established in the business of resilient rail fastenings since 1937. The company gained its present name from the unique Pandrol Brand Rail Clip. This simple, effective rail fastening is suitable for all applications on concrete, timber and steel sleepers and slabtrack, and for use under every type of traffic from simple industrial and mining trackwork through plantation and sugar cane railways, rapid transit and high speed passenger applications (speeds up to 330kph), to the heaviest mineral railway (up to 150 million tons/year). The Pandrol range of rail fastenings is the most widely used in the world and continues to be introduced into new markets.

The present Pandrol rail fastening system is the result of continuous development during the last 30 years. It is this and the technical support the company offers its customers which has established its envied reputation. Extensive laboratory testing and service in track worldwide on over 220 railways has resulted in a simple, reliable, well-proven system suitable for every type of track and traffic condition.

Pandrol rail fastening systems are not a commodity - they are specifically designed for each railway application. Pandrol is not just a manufacturer but a provider of engineered solutions to track problems.

Pandrol has manufacturing plants in 12 countries supplying a total of 82 markets.

Company information

KT15 2AR Addlestone

United Kingdom

TX 76248 Keller

United States of America

700071 Kolkata

India

NSW 2148 Blacktown

Australia

Solutions

- Light Rail

- Rails

Product information

Tram/Light Rail

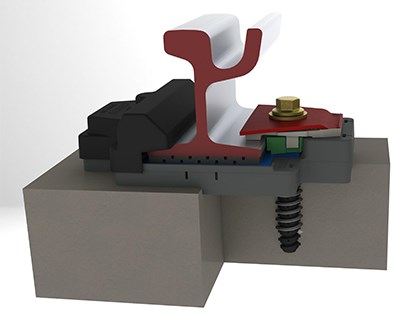

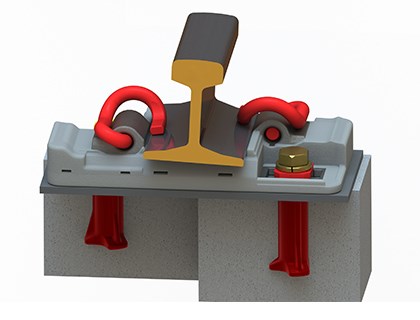

Nabla Tram

The NABLA Tram baseplate is designed to allow effective insertion into a dry mix of fresh concrete thanks to an air evacuation system consisting of blow holes and channels.

The NABLA TRAM FASTENING SYSTEM, compliant with EN standard 13481-5, is designed for use on state-of-the-art tramway tracks. Combining ease-of-application with high performance levels, it is compatible with several track-laying methods, whether Top Down/Bottom Up depending on the

The NABLA TRAM FASTENING SYSTEM, compliant with EN standard 13481-5, is designed for use on state-of-the-art tramway tracks. Combining ease-of-application with high performance levels, it is compatible with several track-laying methods, whether Top Down/Bottom Up depending on the

specific needs of each project. This fastening system features a compositematerial baseplate, NABLA blades are compliant with NF standard F 50-015, NABLA-Evolution stops, a rubber pad, a protective cover and a GS anchoring system.

- Lightweight The lightweight and compact nature of

- Composite material baseplates supports a cost effective construction for Tram LRT Infrastructure.

- Electrical Insulation: Encapsulation of the baseplates by plastic covers provides a high level of electrical insulation. Covers are compatible with most roadway linings, pavement, concrete turf, etc.

- Construction: Baseplates can be installed by innovative slab track construction techniques into fresh dry concrete. NABLA TRAM is also suitable for Top Down wet pour method. Special air evacuation system avoids air getting trapped under the baseplate.

- Hight Performance Dowel: The special GS dowel is suitable for insertion into fresh concrete and transfers loads to the concrete efficiently.

- Tightening To Refusal: Large range of acceptable torque between 250 and 400 Nm allows coachscrew to be tightened to refusal. Toe load is achieved automatically once screw is tightened to refusal.

- Optional Stiffness: Optional static stiffness between 35 MN/mm to 150 MN/mm, based on choice of rail pad. Measurements as per CEN 13481-5: 2012 and CEN 13146-9 Cat A.

High Speed

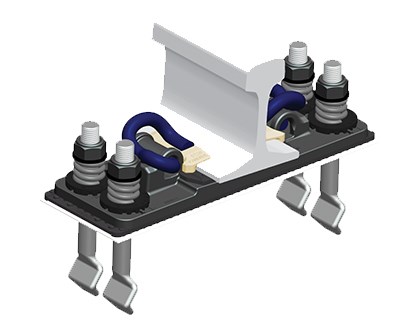

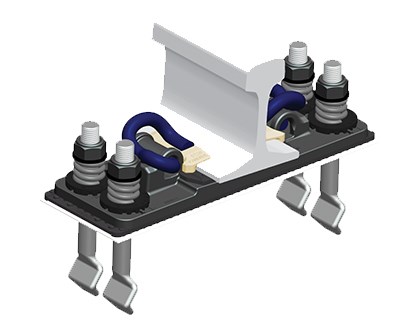

Fastclip SFC

Pandrol FASTCLIP SFC baseplates are designed for use on wet pour top down slabs, pre-cast blocks, sleepers or plinths.

The PANDROL FASTCLIP SFC baseplate system has been designed to easily transfer the advantages of the PANDROL FASTCLIP system to slab track applications. The design allows full advantage to be taken of the PANDROL FASTCLIP captive fastening system, making it an ideal product for non-ballasted trackforms offering high levels of vertical and lateral adjustment. The system is available in three variants. The 2-Hole Offset Baseplate is designed for medium axle load or shallow curve applications. Proven on high speed. 2-Hole In-Line Baseplate is designed for concrete sleepers embedded in precast concrete. Proven on high speed. The 4-Hole Baseplate is designed for installation on slab-track with high axle loads, tight curves, or where compatibility with 4-Hole PANDROL VIPA or PANDROL VANGUARD Baseplates is required.

The PANDROL FASTCLIP SFC baseplate system has been designed to easily transfer the advantages of the PANDROL FASTCLIP system to slab track applications. The design allows full advantage to be taken of the PANDROL FASTCLIP captive fastening system, making it an ideal product for non-ballasted trackforms offering high levels of vertical and lateral adjustment. The system is available in three variants. The 2-Hole Offset Baseplate is designed for medium axle load or shallow curve applications. Proven on high speed. 2-Hole In-Line Baseplate is designed for concrete sleepers embedded in precast concrete. Proven on high speed. The 4-Hole Baseplate is designed for installation on slab-track with high axle loads, tight curves, or where compatibility with 4-Hole PANDROL VIPA or PANDROL VANGUARD Baseplates is required.

- Fully preassembled: pandrol fastclip sfc baseplates are supplied to the track site as fully pre-assembled units.

- Adjustability: pandrol fastclip sfc baseplates provide and exceptionally wide range of adjustment, typically +/- 15 mm lateral per baseplate and + 30 mm vertical. For additional requirements please consult pandrol.

- Dual rail/gauge change: change of rail section is possible through the use of different thickness side post insulators.

- Timber sleepers: a non-adjustable version of the 4-hole pandrol fastclip sfc baseplate is available for timber sleepers.

- Rail free track / structure interaction: low toe load and zero longitudinal restraint (zlr) options are available for use on structures.

- Anchorage: pandrol considers its hold down method as an integral part of the rail fastening design and is happy to provide for specific applications.

- Electrical insulation: electrical insulation is provided by insulating the rail from the baseplate and the clips by the rubber rail pad and nylon side post insulators. A second level of insulation can be provided between the baseplate and slab.

- Installation on site: installation by top down or bottom up by wet pour mounted on pre-cast block, sleeper or slab.

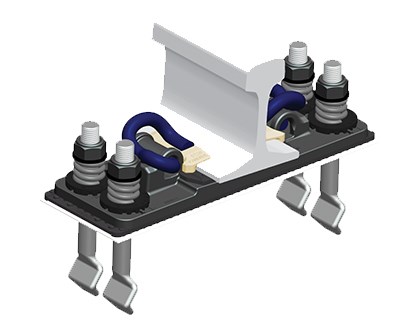

Fastclip FCA

Pandrol FASTCLIP FCA has been designed for use on slab tracks where vertical adjustment is required.

PANDROL FASTCLIP FCA can be assembled at the sleeper factory and delivered to site captive/pre-assembled on the pre-cast element. For top down construction with embedded pre-cast concrete elements. The system can also be provided with an alternative construction plate to facilitate wet pour top-down construction.

PANDROL FASTCLIP FCA can be assembled at the sleeper factory and delivered to site captive/pre-assembled on the pre-cast element. For top down construction with embedded pre-cast concrete elements. The system can also be provided with an alternative construction plate to facilitate wet pour top-down construction.

- Track stiffness: track stiffness typically >40 kn based on cen track category b, c and d. Stiffness can be varied within limits through consultation with pandrol.

- Adjustability: lateral adjustment of +/- 5 mm per rail seat is possible by exchanging side post insulators. Vertical adjustment of +20 mm is possible by component change and shims. For special applications please consult pandrol.

- Fully preassembled: the pandrol fastclip fca system can be delivered to the track site fully pre-assembled/captive and attached to a pre-cast concrete element. Low clamping force and rail free variants are available to address track-structure interaction issues.

- Electrical resistance: the pandrol fastclip fca has two levels of electrical resistance. The rail is isolated from the shoulder by rail pad, side post insulators and toe insulators. The shoulder is insulated from the concrete by a conforming shim and plastic dowels.

- Versatility: bespoke designs can be provided to suit customer operating requirements.

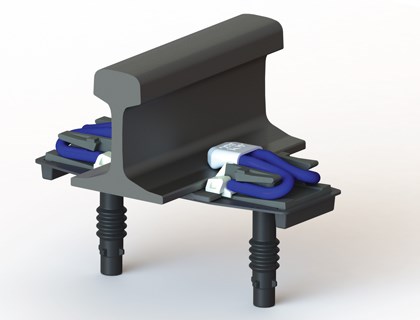

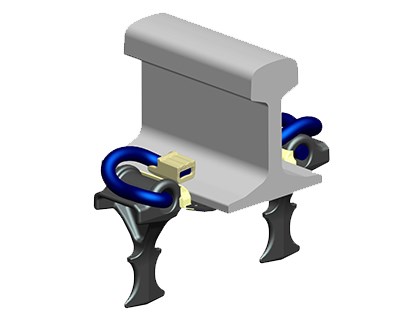

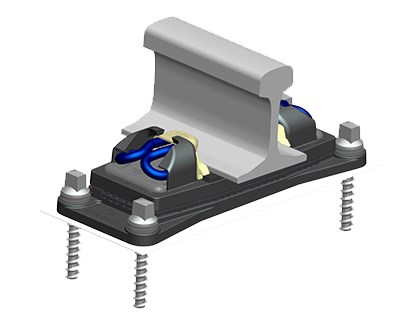

Fastclip FE

The PANDROL FASTCLIP FE system is a resilient, threadless rail fastening system with the unique PANDROL switch on – switch off function that enables fast, efficient track installation and reduced maintenance costs.

Sleepers arrive on site with all components held captive and the clips set at the parked position. Once the sleepers are placed and the rail has been threaded, clips are simply pushed from the parked to the installed position. Correct toe load is achieved automatically.

Sleepers arrive on site with all components held captive and the clips set at the parked position. Once the sleepers are placed and the rail has been threaded, clips are simply pushed from the parked to the installed position. Correct toe load is achieved automatically.

- Fully preassembled: all the components leave the sleeper factory fully pre-assembled on the sleeper, offering huge savings in manpower, and reduced distribution and handling costs during track laying, stressing and rail changing.

- Threadless: the pandrol fastclip system has no threaded components, eliminating costly maintenance.

- Replaceability of components: pandrol fastclip is virtually maintenance free. However, should you need to replace a component, it is a simple procedure to withdraw the clip, without the need to unscrew bolts.

- Rail tensioning / creep resistance: the correct tensioning is automatically achieved when the clip is driven into the working position.

- Anchorage: cast-in shoulders hold the rail at correct gauge and set the fastclip deflection. The shoulders are cast into the sleeper during the manufacturing process.

- Electrical insulation: the fastclip assembly provides excellent electrical insulation properties. The cast shoulders are electrically isolated from the rail by the collars. The spring clips are electrically isolated from the rail by the toe insulators.

- Stressing / neutralisation: all components remain captive during the stressing procedure. The clip is simply withdrawn back to the parked position to release the rail. Stressing rollers are available for use if required.

- Heavy haul: the fe1500 series system is suitable for heavy haul application.

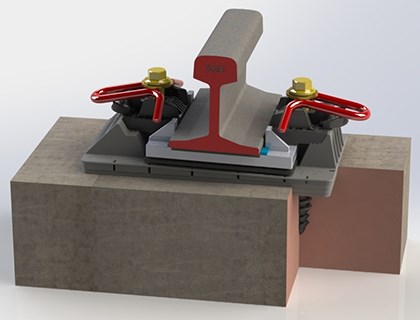

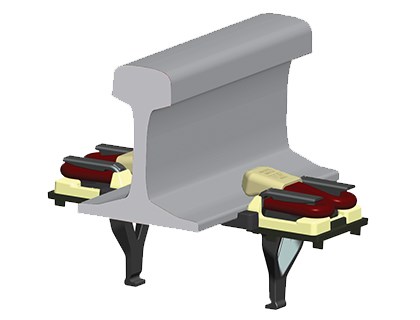

Vipa DRS

The Pandrol VIPA DRS is typically suited for installation on non-ballasted tracks and areas where a reduction in ground borne noise and vibration is required.

The PANDROL e-clip baseplate is mounted on a studded natural rubber pad which provides resilience. This can be tuned, within limits, for axle loads and stiffness requirements. There is no need to grease or re-tighten the fastening elements as the rail fastening elements are non-threaded to provide low maintenance. As with all PANDROL fastenings, the PANDROL resilient baseplate system is backed by many years of worldwide experience and an unmatched depth of technical understanding from PANDROL’s technical engineers.

The PANDROL e-clip baseplate is mounted on a studded natural rubber pad which provides resilience. This can be tuned, within limits, for axle loads and stiffness requirements. There is no need to grease or re-tighten the fastening elements as the rail fastening elements are non-threaded to provide low maintenance. As with all PANDROL fastenings, the PANDROL resilient baseplate system is backed by many years of worldwide experience and an unmatched depth of technical understanding from PANDROL’s technical engineers.

- Experience: systems like this have been in use since the mid 1980s and are installed on mrt and lrt systems in major cities such as hong kong, singapore, sao paulo, dubai and istanbul. It is also installed on main line slab applications and steel bridges on axle loads up to 22.5 tonnes.

- Adjustability: typical lateral adjustment of ±3 mm can be achieved using an eccentric bush, in 1 mm locked steps (additional lateral adjustment can be provided against special requirements). Typical vertical adjustment of up to 20 mm can be achieved using shims.

- Maintenance: all resilient parts and wear components are fully replaceable in-situ. The system has two independent levels of electrical insulation and uses pandrol threadless fastening technology, providing low maintenance throughout the life of the system.

- Installations: pandrol resilient baseplate assemblies can be installed using either top down or bottom up construction methods.

LRT/Metro

Bonded DFF: ADH

The Bonded DFF:ADH fastening system has 2 solutions available. A standard model valid for running track, and customised models for switching zones.

The Bonded DFF:ADH fastening system has 2 solutions available. A standard model valid for running track, and customised models for switching zones.

The Bonded DFF ADH system has been developed to directly combat corrugation and vibration problems caused by major dynamic forces generated from passing trains. Drawing on some 30 years’ experience and feedback from over 400,000 units fitted worldwide, the DFF ADH system is suited to raillaying on concrete sleepers and slabs. It can also accommodate the different resilient fasteners proposed by Pandrol Track Systems : NABLA, SD, e-clip, FASTCLIP, SKL and G4.

- Vertical and lateral stiffness: the dff adh bonded system provides both vertical and lateral stiffness as two independent cast baseplates are assembled by bonding using vulcanized rubber.

- Vibration attenuation: vibration isolation is provided in a range of stiffness down to 10.5 kn/mm. Standard stiffness typically 20 kn/mm, bespoke requirements can also be accommodated.

- Electrical insulation: very high levels of electrical resistance are achieved as a result of the bonding process which provides long electrical leakage paths and test results to en standards several times higher than the minimum required.

- Transfer of lateral forces: lateral forces are transferred from the rail through the baseplate and into the rubber, thus minimising the forces transferred into the anchor bolts and reducing risk of bolt failure.

- Construction: the dff adh bonded baseplate comprises a single unit which can be installed by top down method or installed on pre-cast blocks, sleepers or slabs. Vertical adjustment of typically 30 mm and lateral adjustment +/-12 mm.

- Other applications: the dff adh system can be provided in various lengths to suit turnout applications and are also suitable for steel bridges and ballasted tracks.

VIPA DRS

The Pandrol VIPA DRS is typically suited for installation on non-ballasted tracks and areas where a reduction in ground borne noise and vibration is required.

The PANDROL e-clip baseplate is mounted on a studded natural rubber pad which provides resilience. This can be tuned, within limits, for axle loads and stiffness requirements. There is no need to grease or re-tighten the fastening elements as the rail fastening elements are non-threaded to provide low maintenance. As with all PANDROL fastenings, the PANDROL resilient baseplate system is backed by many years of worldwide experience and an unmatched depth of technical understanding from PANDROL’s technical engineers.

The PANDROL e-clip baseplate is mounted on a studded natural rubber pad which provides resilience. This can be tuned, within limits, for axle loads and stiffness requirements. There is no need to grease or re-tighten the fastening elements as the rail fastening elements are non-threaded to provide low maintenance. As with all PANDROL fastenings, the PANDROL resilient baseplate system is backed by many years of worldwide experience and an unmatched depth of technical understanding from PANDROL’s technical engineers.

- Experience: systems like this have been in use since the mid 1980s and are installed on mrt and lrt systems in major cities such as hong kong, singapore, sao paulo, dubai and istanbul. It is also installed on main line slab applications and steel bridges on axle loads up to 22.5 tonnes.

- Adjustability: typical lateral adjustment of ±3 mm can be achieved using an eccentric bush, in 1 mm locked steps (additional lateral adjustment can be provided against special requirements). Typical vertical adjustment of up to 20 mm can be achieved using shims.

- Maintenance: all resilient parts and wear components are fully replaceable in-situ. The system has two independent levels of electrical insulation and uses pandrol threadless fastening technology, providing low maintenance throughout the life of the system.

- Installations: pandrol resilient baseplate assemblies can be installed using either top down or bottom up construction methods.

DEE:SD

Completely pre-assembled from anchoring dowels to fastenings, the system is suited to all track-construction types.

This elastic two-stage system, compliant with EN Standard 13481-5 categories A and B (tramway and metro applications) is designed to reduce structure-borne noise produced by rail/wheel contact and to attenuate vibrations. As with all Pandrol fastenings, the DEE SD system is backed by many years of worldwide experience and unmatched depth of technical understanding from Pandrol’s technical engineers.

This elastic two-stage system, compliant with EN Standard 13481-5 categories A and B (tramway and metro applications) is designed to reduce structure-borne noise produced by rail/wheel contact and to attenuate vibrations. As with all Pandrol fastenings, the DEE SD system is backed by many years of worldwide experience and unmatched depth of technical understanding from Pandrol’s technical engineers.

- Lightweight: the lightweight and compact nature of composite material baseplates supports a cost effective construction for tram lrtand metro infrastructure.

- Low vertical stiffness: vertical stiffness typically 25 kn/mm reduces noise and vibration transmission.

- Adjustment: vertical height adjustment of +16 mm, lateral adjustment +/- 5 mm. Higher values may be proposed depending on project specification.

- Construction: baseplates can be installed by innovative slab track construction techniques into fresh dry concrete. Dee sd is also suitable for top down wet pour method. Special air evacuation system avoids air getting trapped under the baseplate.

- High performance dowel: the special gs dowel is suitable for insertion into fresh concrete and transfers loads to the concrete more efficiently.

- Tightening to refusal: large range of acceptable torque between 250 and 400 nm allows coachscrew to be tightened to refusal. Toe load is achieved automatically once screw is tightened to refusal.

- Optional stiffness: optional static stiffness between 35 kn/mm to 150 kn/mm, based on choice of rail pad.

Passenger/Freight

Re System

The Pandrol Re System adopts the two-part insulator concept that was developed with the Pandrol FASTCLIP system.

The PANDROL Re SYSTEM delivers an assembly with faster installation times and a reduced number of components when compared to a traditional e-clip equivalent. This can lead to more productive engineering possessions for track refurbishment. With the PANDROL Re SYSTEM, the rail pad is supplied with the side post insulators already attached, reducing time and labour when laying out and installing the components on site. The Re SYSTEM is also supplied with toe insulators already in place on the toe of the clip, again reducing installation time and the number of loose components on site.

The PANDROL Re SYSTEM delivers an assembly with faster installation times and a reduced number of components when compared to a traditional e-clip equivalent. This can lead to more productive engineering possessions for track refurbishment. With the PANDROL Re SYSTEM, the rail pad is supplied with the side post insulators already attached, reducing time and labour when laying out and installing the components on site. The Re SYSTEM is also supplied with toe insulators already in place on the toe of the clip, again reducing installation time and the number of loose components on site.

- Retrofit: the pandrol re system retro ts on existing pandrol e-clip and pr clip assemblies.

- Component wear: improved durability of insulators by separating function of toe and sidepost insulator.

- Efficiency gains: by providing side post insulators and rail pads as single components a number of effiencies are created.

- Fewer components to handle

- Opportunity to mechanise pad installation

- Eliminates individual placing of insulators

- Facilitates easier rail threading

- Optional rail pads: rail pads can be provided in different materials and stiffness, such as eva, grooved rubber, studded rubber, pu etc.

- Heavy haul: heavy haul applications can be provided, consult pandrol for details.

Fastclip FE

The PANDROL FASTCLIP FE system is a resilient, threadless rail fastening system with the unique PANDROL switch on – switch off function that enables fast, efficient track installation and reduced maintenance costs.

Sleepers arrive on site with all components held captive and the clips set at the parked position. Once the sleepers are placed and the rail has been threaded, clips are simply pushed from the parked to the installed position. Correct toe load is achieved automatically.

Sleepers arrive on site with all components held captive and the clips set at the parked position. Once the sleepers are placed and the rail has been threaded, clips are simply pushed from the parked to the installed position. Correct toe load is achieved automatically.

- Fully preassembled: all the components leave the sleeper factory fully pre-assembled on the sleeper, offering huge savings in manpower, and reduced distribution and handling costs during track laying, stressing and rail changing.

- Threadless: the pandrol fastclip system has no threaded components, eliminating costly maintenance.

- Replaceability of components: pandrol fastclip is virtually maintenance free. However, should you need to replace a component, it is a simple procedure to withdraw the clip, without the need to unscrew bolts.

- Rail tensioning / creep resistance: the correct tensioning is automatically achieved when the clip is driven into the working position.

- Anchorage: cast-in shoulders hold the rail at correct gauge and set the fastclip deflection. The shoulders are cast into the sleeper during the manufacturing process.

- Electrical insulation: the fastclip assembly provides excellent electrical insulation properties. The cast shoulders are electrically isolated from the rail by the collars. The spring clips are electrically isolated from the rail by the toe insulators.

- Stressing / neutralisation: all components remain captive during the stressing procedure. The clip is simply withdrawn back to the parked position to release the rail. Stressing rollers are available for use if required.

- Heavy haul: the fe1500 series system is suitable for heavy haul application.

VIPA DRS

The Pandrol VIPA DRS is typically suited for installation on non-ballasted tracks and areas where a reduction in ground borne noise and vibration is required.

The PANDROL e-clip baseplate is mounted on a studded natural rubber pad which provides resilience. This can be tuned, within limits, for axle loads and stiffness requirements. There is no need to grease or re-tighten the fastening elements as the rail fastening elements are non-threaded to provide low maintenance. As with all PANDROL fastenings, the PANDROL resilient baseplate system is backed by many years of worldwide experience and an unmatched depth of technical understanding from PANDROL’s technical engineers.

The PANDROL e-clip baseplate is mounted on a studded natural rubber pad which provides resilience. This can be tuned, within limits, for axle loads and stiffness requirements. There is no need to grease or re-tighten the fastening elements as the rail fastening elements are non-threaded to provide low maintenance. As with all PANDROL fastenings, the PANDROL resilient baseplate system is backed by many years of worldwide experience and an unmatched depth of technical understanding from PANDROL’s technical engineers.

- Experience: systems like this have been in use since the mid 1980s and are installed on mrt and lrt systems in major cities such as hong kong, singapore, sao paulo, dubai and istanbul. It is also installed on main line slab applications and steel bridges on axle loads up to 22.5 tonnes.

- Adjustability: typical lateral adjustment of ±3 mm can be achieved using an eccentric bush, in 1 mm locked steps (additional lateral adjustment can be provided against special requirements). Typical vertical adjustment of up to 20 mm can be achieved using shims.

- Maintenance: all resilient parts and wear components are fully replaceable in-situ. The system has two independent levels of electrical insulation and uses pandrol threadless fastening technology, providing low maintenance throughout the life of the system.

- Installations: pandrol resilient baseplate assemblies can be installed using either top down or bottom up construction methods.

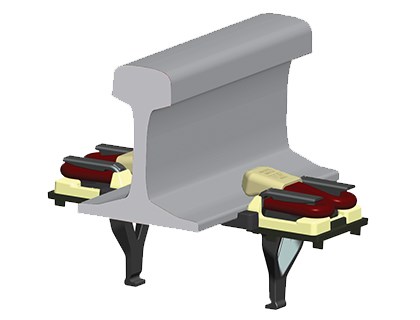

Vipa SP

Pandrol VIPA SP assemblies are supplied to the track site as assembled units. The system is available in two variants.

PANDROL VIPA SP is a resilient track support system that has been developed to attenuate the wheel/rail contact induced vibrations that are transferred from the rail to the supporting structure. The concept is based on providing support through a two layer resilient pad system. PANDROL VIPA SP assemblies are available for fixation to timber, steel or concrete supporting structures. The system is available in two variants. The 2-hole o set baseplate is designed for medium axle loads or high speed. The 4-Hole Baseplate is designed for higher axle loads or tight curves or, where compatible, interchangeability with PANDROL VANGUARD baseplates.

PANDROL VIPA SP is a resilient track support system that has been developed to attenuate the wheel/rail contact induced vibrations that are transferred from the rail to the supporting structure. The concept is based on providing support through a two layer resilient pad system. PANDROL VIPA SP assemblies are available for fixation to timber, steel or concrete supporting structures. The system is available in two variants. The 2-hole o set baseplate is designed for medium axle loads or high speed. The 4-Hole Baseplate is designed for higher axle loads or tight curves or, where compatible, interchangeability with PANDROL VANGUARD baseplates.

- Adjustability: pandrol vipa sp baseplates provide and exceptionally wide range of adjustment, typically +/- 15 mm lateral per baseplate and +30 mm vertical. For additional requirement please consult pandrol.

- Maintenance: pandrol vipa is a non-bonded baseplate assembly designed for long life. All parts are fully accessible and replaceable, thus offering reduced maintenance costs as the entire unit does not need to be replaced.

- Electrical insulation: double electrical insulation is provided by insulating the rail from the top plate, and the top plate from the baseplate by the rubber pads, bushes and nylon insulators.

- Rail free track / structure interaction: low toe load and zero longitudinal restraint (zlr) options are available for use on structures.

- Track stiffness: standard pandrol vipa assemblies are designed to provide static vertical secant stiffness >15 kn/mm. Changes in stiffness can be provided to accommodate local requirements.

- Anchorage: pandrol considers the hold-down method an integral part of the rail fastening design, and is happy to advise accordingly for specific applications. The degree of vertical adjustment provided is determined by the anchor arrangement selected. Various options are available.

- Installation: two different methodologies exist for track construction: ‘top down’ and ‘bottom up’. Pandrol vipa can be installed using either method. Pandrol vipa can be installed by top down wet pour with or without pre-cast concrete elements. Also suitable for installation on timber or steel bearers/bridge beams.

Press releases

- Pandrol’s Road Rail Trailer approved for full use in Norway

- Pandrol begins partnership with Alom in the Netherlands

- Innovative application of rail fastenings for HS2

- RAPID DELIVERY IN MALAYSIA

- Trafikverket selects the latest generation Pandrol fastening system

- Metro-North Railroad Contract 9622-A - Awarded to Vortok

- First tracks laid for Sydney’s $2.1b light rail project

- Innovation Award Success

- Light Rail Transit Success in Taiwan