Amsted Rail

Visiting address

South Wacker Drive 311

IL 60606

Chicago

Postal address

South Wacker Drive 311

Chicago , IL 60606

Contact person

Stephen BeckerJoin our community for FREE today!

Create and share your own profile

Join the discussions

Publish your own items

Subscription to our Weekly eNewsletter

Get connected with Mass Transit Professionals Worldwide

FREE membership benefits

- * create and share your own profile

- * join the discussions

- * publish your own items on Mass Transit Networkmanage news, jobs, tenders, companies, events, showcases, educations, associations and literature.

- * subscribe to our eNewsletter

Company information

The World is turning to Amsted Rail®

Industry leaders for more than 100 years, heavy haulers count on Amsted Rail® to perform in the world’s toughest rail environments. Our experience in designing heavy-haul equipment is unequalled, and our industry-leading innovations make it possible for railroads all over the world to haul heavier loads over greater distances with improved reliability and performance.

Amsted Rail® Highlights

- Largest Freight Car Component Manufacturer in the World

- Industry Leaders in wheels, bearings, side frames & bolsters, and rail anchors.

- Privately Held & Employee Owned

- Operations on Six Continents

Rooted in Strength

Amsted Rail® is proud to be a part of Amsted Industries Corporation. A diversified manufacturer of highly engineered industrial components, Amsted Industries is a leader in the railroad, vehicular and construction markets. Privately held with manufacturing facilities in over 10 countries, Amsted Industries employs more than 10,000 people.

Company information

IL 60606 Chicago

United States of America

Solutions

- Components for Railbound Vehicles

- Mechanical Components

- Wheels

Product information

Locomotive Parts

Axles

Amsted Rail®®, through its AXIS Worldwide operation, manufactures railroad axles to the most exacting standards in the world. Operating the industry’s most technologically advanced axle manufacturing facility, AXIS produces over 50 different types of railroad axles, and has the capability to manufacture virtually any type of railroad axle used in the world today.

Amsted Rail®®, through its AXIS Worldwide operation, manufactures railroad axles to the most exacting standards in the world. Operating the industry’s most technologically advanced axle manufacturing facility, AXIS produces over 50 different types of railroad axles, and has the capability to manufacture virtually any type of railroad axle used in the world today.

Key Facts

- Forging: Fully automated, in-line radial hot forging machine, performing 380 forming steps per minute while maintaining the tightest tolerances in the industry. Pre-heating of raw material up to 2300°F (1250°C) before forging.

- Heat Treating: Furnaces capable of heating steel to over 1800°F (980°C) can heat treat parts weighing up to 4,000 Lbs (1800 Kg) and 18 Ft (5.5 m) in length.

- Machining: Multiple lathes combined with end facing/centering/drilling/tapping machines produce an axle from this fully automated system at a rate of one axle in less than three minutes, produced within a tolerance of +/- .0005 inches (+/- .0127 mm.)

Benefits

- Highly automated manufacturing system provides a higher degree of precision, assuring that axles conform to your most rigorous requirements.

- Axles are produced in accordance with your quality system requirement. Association of American Railroads (AAR) M-101 and M-1003, Indian Railways IRS R 16-95, EN 13261, South Africa SPOORNET RS/ME/SP/002.

- In-line automated inspection equipment and certified level II and III NDT inspectors assure consistent, superior quality.

- Global logistics capability assures axles will arrive on time, every time anywhere in the world.

- ISO 9001:2008 Certified.

Product Line

- Rough machined; ±0.04” (1 mm) tolerance

- Semi-finished; Includes Drill and Tapped Holes

- Finished; ±0.00085” (0.02 mm) tolerance

Coil Springs

ASF-Keystone®® spring manufacturing is differentiated by its excellent process control, which assures consistency of dimensional, metallurgical and functional properties in final products.

ASF-Keystone®® spring manufacturing is differentiated by its excellent process control, which assures consistency of dimensional, metallurgical and functional properties in final products.

Our engineers have extensive experience in custom designing springs for the most demanding requirements.

All ASF-Keystone®® spring manufacturing processes include shot peening and heat-treating.

Draft Gears

ASF-Keystone®® Locomotive Draft Gears have been the standard of the industry for more than 30 years. Utilizing our Key-Gard™ elastomer, our gears provide superior buff and draft protection in even the heaviest locomotive applications.

Key Facts

- Used in freight switchers (485 Series) and road units (390 / 391 Series).

- Used in passenger service (488 and 489 series).

- The 390/391 series gears are available with heavy-duty alignment control for anti-jackknifing protection.

Benefits

- Gears provide superior buff and draft protection in even the heaviest locomotive applications.

Product Line

- Proprietary Locomotive Draft Gears

Tapered Roller Bearings

Our OEM facility for manufacturing Class GG Locomotive bearings is located in Petersburg, Virginia.

Our OEM facility for manufacturing Class GG Locomotive bearings is located in Petersburg, Virginia.

Key Facts

OEM (Class GG)

- This super heavy-duty bearing was designed specifically to meet the higher demands of locomotive service.

- Equipped with Polyamide Cages as a standard

- Ring rolled forgings provide optimal raceway life

- Available in 6 7/8" and 6 1/2" bore sizes

Reconditioned (Class GG)

- Available through our Authorized Remanufacturer.

Wheels

Griffin®® has been in full production of diesel wheels since 1966. Using our proven design, we produce diesel wheels cast to such close tolerances that they are better balanced than most steel wheels. Such balance contributes to maximum traction, smooth ride, and longer wheel life.

Griffin®® has been in full production of diesel wheels since 1966. Using our proven design, we produce diesel wheels cast to such close tolerances that they are better balanced than most steel wheels. Such balance contributes to maximum traction, smooth ride, and longer wheel life.

Key Facts

All Griffin®® diesel wheels have witness grooves so the recontouring operation will better produce matched tapes throughout the locomotive.

Product Line

- Griffin® diesel wheels are available in:

- T40 – 41” diameter with 3.0” rim

- D42 – 42” diameter with 2.5” rim

- A43 – 43” diameter with 3.0” rim

IONX Asset Monitoring

Solutions

Combining M2M communications with GPS, IONX systems deliver near real time data to better manage fleet operations and improve financial performance. With IONX you can increase the visibility of mobile assets, improve logistics management, identify supply chain bottlenecks, and receive immediate notification of critical events. IONX provides comprehensive solutions customized to meet the needs of fleet managers in many industries.

Combining M2M communications with GPS, IONX systems deliver near real time data to better manage fleet operations and improve financial performance. With IONX you can increase the visibility of mobile assets, improve logistics management, identify supply chain bottlenecks, and receive immediate notification of critical events. IONX provides comprehensive solutions customized to meet the needs of fleet managers in many industries.

IONX offers an array of wireless sensor applications to meet any of your needs, customizable for every commodity and asset type. These sensors provide secure information, all from a highly sophisticated, encrypted network, and all at your fingertips.

Monitoring Reports

IONX provides data that enables you to gain visibility of your rail and locomotive assets to see location and condition status in near real time.

Our customizable Web-based dashboards give the right information to the right managers at the right time so they have comprehensive information essential to managing your fleet’s performance, condition and security.

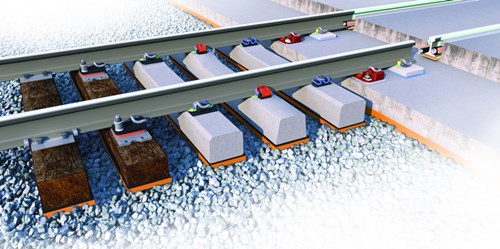

Track

For over 150 years, Amsted RPS has lead the Industry in rail fastening systems, providing fasteners for every type of track – heavy haul, high speed and transit.

Key Facts

- Quality: Amsted RPS is ISO and AAR certified, and for more than 150 years has been meeting the demanding needs of needs of our customers in the harshest track conditions.

- Employee Experience: Every Amsted RPS employee averages over 10 years in length of service with many employees topping the 30-year mark.Innovation: From the concrete tie Captive System to ATP´s Loadmaster, Amsted RPS is leading the charge toward creating innovative, applicable products for today’s railroad environments.

Benefits

- Quick turn around on all customer orders.

- In-house design capabilities allow us to work with our customers to meet any requirements for track fasteners.

Product Line

- Wood/Composite Ties

- Concrete/Steel Ties

- Advanced Products for Vibration Management

- Specialty Tools for Efficient Track Maintenance