Evac Train

Visiting address

Feldstrasse 124

22880

Wedel

Postal address

Feldstrasse 124

Wedel , 22880

Contact person

Hans WörmckeJoin our community for FREE today!

Create and share your own profile

Join the discussions

Publish your own items

Subscription to our Weekly eNewsletter

Get connected with Mass Transit Professionals Worldwide

FREE membership benefits

- * create and share your own profile

- * join the discussions

- * publish your own items on Mass Transit Networkmanage news, jobs, tenders, companies, events, showcases, educations, associations and literature.

- * subscribe to our eNewsletter

Company information

Evac - The System Integrator

Complete Sanitary System Solutions for Trains

A sanitary system is more than the sum of the components it is using. That is why Evac focusses on the complete integrated sanitary system for trains.

Evac´s almost 50 years expertise in railway applications has been generating state-of-the-art components with “built-in” field experience of more than 70.000 vacuum systems installed worldwide.

Company Objectives

People

The employees represent Evac’s greatest potential. Evac supports creativity, initiative, willingness to take over responsibility and continuous learning and personal development.

Cooperation

Evac is a reliable partner and fully cooperates with its customers. This also shows in the cooperation with contract partners, suppliers and consultants.

Customers

Evac is well aware of customer’s requirements.The definition of Evac products and service guarantees the optimum compliance with customer’s requirements. This applies to quality of products and services as well as to prices and observing confirmed target dates. Evac understands that customer satisfaction is the key for a long term business relationship.

Market

Evac supplies its products and services to all relevant markets around the world. Evac holds the largest respective market share in all markets worldwide.

Technology

Evac is worldwide technology leader. Evac is skilled supplier of integrated systems and components for sanitary modules in trains and buses. Evac continually improves its products in terms of functionality and reduction of life cycle cost at the same time. Evac generates ideas by research and development in its market segment and develops new, marketable products by use of modern technology. Evac uses its widespread experience to develop new services and is the competent contact for customer requirements.

Processes

Evac’s business environment is constantly changing and internal processes will always show potential for further improvement.

Therefore Evac continually improves its internal processes. The individual commitment of every

employee is of essential relevance to do so.

Business Development

Evac aims to be in the market on long term. This can only be achieved based on a sound development of the business. Thus Evac strives for economic success of its operation.

Quality

Evac is committed to anticipating, understanding and meeting its customers’ needs and expectations. Our zero defect objective combined with full adherence to delivery dates and quantity stipulations postulate a reliable control of workflows and processes from development to serial delivery of our toilet systems.

With a passion for customer adaptations we provide outstanding support to make our customers successful. Evac GmbH delivers superior value through continuos improvement and a dedication to service and reliability.

Our quality management system is designed for a special market and our global presence. Evac GmbH is certified to ISO 9001 and International Railway Industry Standard IRIS.

Company information

22880 Wedel

Germany

Solutions

- Sanitary

Product information

Vacuum toilet system

Evac Compact

Microprocessor controlled system with integrated fault detection and correction.

Compact and space saving design for optimal integration into toilet cabins of newly built trains and installation as retrofit units in coach renovation and refurbishment programs. Quick and easy installation. Only approx. 0.5 liters water consumption per flush. The bowl is flushed with high pressure water.

1 Control unit

2 Water tank with integrated level sensor

3 Intermediate tank

4 Sliding gate valve

Evac Compact Pv

Microprocessor controlled system with integrated fault detection and correction.Compact and space saving design for optimal integration into toilet cabins of newly built trains and installations as retrofit units in coach renovation and refurbishment programs. Quick and easy installation. Only approx. 0.5 liters water consumption per flush. Pinch valve with closed housing, optimized control program and material to prolong product life. A redundant safety system is preventing backflush.

1 Water tank with integrated level sensor

2 Pinch valve

3 Control unit

Evac 2000 E

The system operates with an intermittent vacuum. During every flush a vacuum is created in the retention tank. The system has an advanced electronic control panel with a wide range of alarm, control and indication functions. The operational vacuum level is according to customers piping lay out and application.

1 Sliding gate valve

2 Control unit

3 Water tank with integrated level sensor

4 Supply interface (Water, electrical power,compressed air)

Evac 2000 P

The system operates with a constant pre-set vacuum level that is controlled by a vacuum switch mounted on the waste water tank. The flushing and the discharge of the toilet bowl is controlled by a vacuum operated pneumatic controller. The electric control for the remaining systeSpeichernm is reduced to support some solenoid valves and the tank level indication. The water consumption per flush can be minimized to 0.5 liter. This system is a very interesting cost efficient and simplified alternative to the EVAC 2000E. It shows a high grade of reliability.The system components have a proven track record in operation in more than 700.000 Evac toilet applications (marine, building, train).

1 Suction protection

2 Outlet valve

3 Vaccum operated pneumatic controller

Evac Online

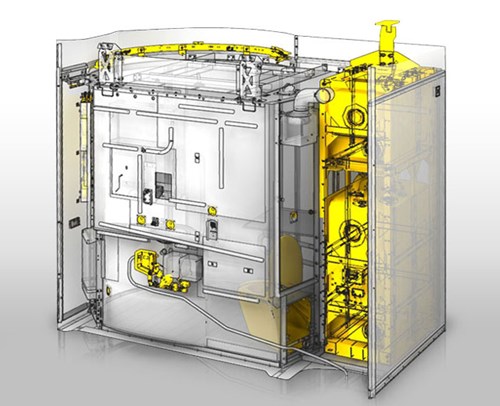

The online concept is the optimum solution developed for both new coaches and refurbishment programs. The system can easily be combined with a wide range of Evac components to meet customer specification and requirement. The system's high level of reliability results from its tried and tested components, the design of which has evolved from many years of operational experience and the corresponding expertise. All system components can easily integrated into the coaches. Several online systems can be connected to one common waste water tank. Evac online ejector can be used with 2000E vacuum toilets.

1 Sliding gate valve

2 Control unit

3 Water tank with integrated level sensor

Online ejector with box

Control system

Evac offers a wide range of flexible, easy to maintain and cost efficient control systems. Both conventional as well as mixed or complete bus based solutions are available. Furthermore Evac is capable of providing network interfaces to our customer. For example: potential free contacts, CAN-Bus, Ethernet, Profibus and many more are available on request.

Water system

With Evac’s long business experience in the field of water supply and sanitation we are able to manage your complete water system. Evac provides fresh water systems equipped with tanks, heating systems, pumps, water heater, mixing valves, freeze draining solutions etc. Furthermore, we offer entire waste water treatment including grey and black water sanitation.

Accessories

In order to complete Evac s portfolio a variety of usefull accessories can be offered.There are for example: Tank level indicator panels, push buttons, combined door close, door lock and unlock buttons, indicators, IR-Sensor, audible message systems (acc. TSI-PRM), cabin lighting, hand dryer, cabin heating systems etc

Evac Enviroclean System

EnviroClean is an accessory for vacuum toilets to keep toilets and piping clean, sanitized and free of deposit. During each flush cycle a small amount of EnviroClean solution is added to the flush water, Dosing pump for EnviroClean solution is positioned on the flush water conduit between flush water tank and flush nozzles.

Tank

Evac offers a wide choice of fresh and waste water tanks. Evac tanks are made of PE or stainless steel, applications are inside the train compartment as well as underfloor with integration to the trains exterior design. Evac tanks are designed by Evac itself including all FEM calculations. As a system integrator, Evac offers tanks fully equipped and ready for operation.

Door mechanism

Evac's integrated door system, consists of door mechansim and door control unit, covers customer demand both for safety as well as reliability and availability.With Evac s know-how, built-on many years of experience and continious improvement, we are able to offer fully developed and cost efficient door systems compliant to all relevant railway standards.

Cabin

The use of highest quality and highest reliability components is fundamental to meet ever increasing reliability requirements of the market. Evac´s almost 40 years expertise in railway applications has been generating state-of-the-art components with “built-in” field experience of more than 50.000 vacuum systems installed worldwide.