Furrer + Frey

Visiting address

Thunstrasse 35

3000

Bern

Postal address

PO Box: 182

PO Box 182

Bern , 3000

Contact person

Beat FurrerJoin our community for FREE today!

Create and share your own profile

Join the discussions

Publish your own items

Subscription to our Weekly eNewsletter

Get connected with Mass Transit Professionals Worldwide

FREE membership benefits

- * create and share your own profile

- * join the discussions

- * publish your own items on Mass Transit Networkmanage news, jobs, tenders, companies, events, showcases, educations, associations and literature.

- * subscribe to our eNewsletter

Company information

Emil Furrer and Arnold Frey founded the electrical overhead line contact organistaion of Furrer + Frey in 1923. During this period the implentations of electrification for Switzerland's railways were in progress. The company have been making overhead contact line systems ever since and has grown considereably to meet the ever increasing global demands.

Company information

3000 Bern

Switzerland

WC1R 4EB London

United Kingdom

00125 Rome

Italy

8005 Zürich

Switzerland

Solutions

- Maintenance

- Overhead Lines

Product information

Systems

FL 200 and FL 260

FL 200/FL 260 is a versatile Overhead Contact Line System. For speeds up to 200 kmph no stitch wires are required. All its components are made exclusively of corrosion-resistant materials. The cantilevers are made of stainless-steel or Aluminium tubes. All components are listed in our catalogue and the arrangement of assemblies is described in our assembly manual. Allocation design is assisted by our 3D-CAD tool ELFF.

FL 200/FL 260 is a versatile Overhead Contact Line System. For speeds up to 200 kmph no stitch wires are required. All its components are made exclusively of corrosion-resistant materials. The cantilevers are made of stainless-steel or Aluminium tubes. All components are listed in our catalogue and the arrangement of assemblies is described in our assembly manual. Allocation design is assisted by our 3D-CAD tool ELFF.

- More than 200 km of FL 200 have been constructed or planned for eight Swiss railway companies to date.

- The Federal German Railways Office in Bonn has approved the overhead contact line systems FL 200/FL 260 for use on the net of the DB AG and Network Rail is installing FL200-GEFF on its Great Eastern Line.

- The Railway Cert (EBC) granted us the certificate for interoperability in 2004.

Series 1

Series 1 is the new overhead line equipment range for routes above 110mph to be electrified. It is being implemented on the Great Western Route.

Series 1 is the new overhead line equipment range for routes above 110mph to be electrified. It is being implemented on the Great Western Route.

EisenbahnCert certified Series 1's compliance with TSI Energy for Conventional Rail and for High Speed.

Series 1 has been designed in conjunction with Network Rail's High Output Plant System HOPS in order to minimise installation times and track possessions.

Its main features are:

- Single insulator cantilevers "SIC" with a reduced number of components; simply to be hooked on to the pre-installed attachment on the mast

- Two Track Cantilever booms for Adjacent Line Open working and quick lift and land installation.

- Mono-Anchor-Booms for easy wiring.

- Single Span overlaps for efficient use of tension length.

Conductor Rail

Rigid Overhead Conductor Rail System (ROCS) for narrow tunnels, high reliability and for special applications. Practical Experience since 1984, now for up to 250km/h

Rigid Overhead Conductor Rail System (ROCS) for narrow tunnels, high reliability and for special applications. Practical Experience since 1984, now for up to 250km/h

Fault-free experience has been acquired since 1984. Over one hundred thirty tunnels, one hundred twenty depots, a dozen bridges and numerous special applications have been realized throughout the world, and on some stretches trains travel at speeds of up to 250 km/h. During test runs the speed of 302 km/h was reached.

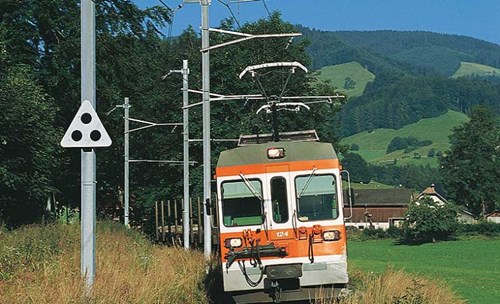

Light rail

Light Rail is the answer to track-bound public transport in urban areas. Public authorities, adjoining residents and users of Light Rail systems set store by the integration of fixed systems within existing urban or local surroundings. Slim tubular cantilevers and cables in synthetic material are easy on the eyes and can be matched in colour to their environment.

Light Rail is the answer to track-bound public transport in urban areas. Public authorities, adjoining residents and users of Light Rail systems set store by the integration of fixed systems within existing urban or local surroundings. Slim tubular cantilevers and cables in synthetic material are easy on the eyes and can be matched in colour to their environment.

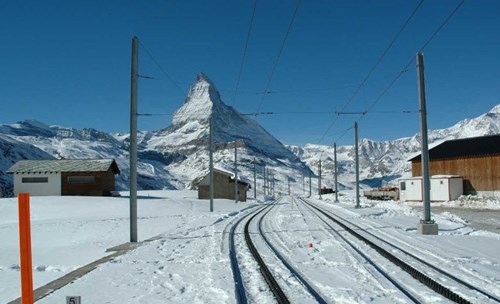

Fixed Catenary OLE

The OLE system has to adapt to the sinuous lines in the mountains. Fixed Catenary OLE - vertical or inclined

The OLE system has to adapt to the sinuous lines in the mountains. Fixed Catenary OLE - vertical or inclined

Right from the pioneering stage of railway construction, Switzerland's topographical conditions have determined the lay of the line. Even to this day, narrow radii decide the speed at which a line may be travelled and maximums of 80 to 100 kmph are the rule in some cases. For reasons of economy, semi-tensioned contact line systems were chosen when electrifying these lines and have stood the test of time to the present day.

Dual-pole OLE systems

Dual-pole overhead contact lines for 3-phase railways or trolleybusses are also in our range of products

Dual-pole overhead contact lines for 3-phase railways or trolleybusses are also in our range of products

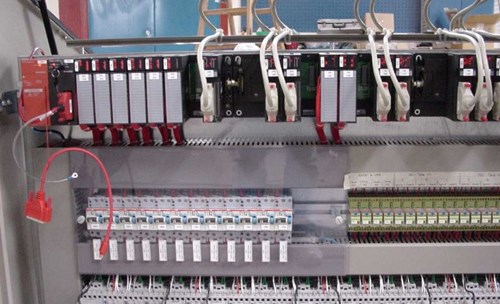

Railway Control Systems

Railway control systems for depots to control and supervise the switching and earthing process of the overhead contact lines in a safe manner.

Railway control systems for depots to control and supervise the switching and earthing process of the overhead contact lines in a safe manner.

The control system is composed of a Main Control Cabinet and components for controlling, signalling and supervising isolators and locks on earth rods, ladders, platforms etc.

Rapid Charge Station

Fast charged electric and hybrid buses require a charging station to transfer large amounts of power from the electric grid to the bus. For this purpose Opbrid Bůsbaar has chosen a well proven Furrer+Frey moveable conductor rail system.

Fast charged electric and hybrid buses require a charging station to transfer large amounts of power from the electric grid to the bus. For this purpose Opbrid Bůsbaar has chosen a well proven Furrer+Frey moveable conductor rail system.

Design

Engineering

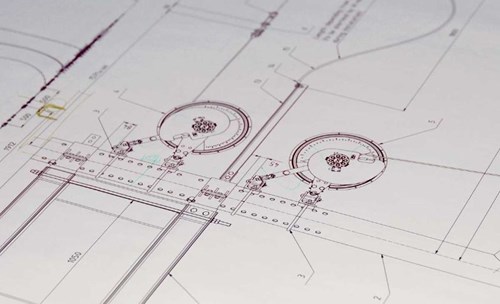

Overhead Contact Line Design - Our engineering team are highly trained technicians who work extensively with computer software planning aids, such as AutoCAD, falp 2.0 (©Furrer+Frey, contact line configuration sooftware) and the 3D planning tool ELFF (©ELBAS/Furrer+Frey). Since 1999 we have SBB's mandate to maintain their design tool FACDA. Moreover, we are using other common tools such as Inventor or Microstation.

Overhead Contact Line Design - Our engineering team are highly trained technicians who work extensively with computer software planning aids, such as AutoCAD, falp 2.0 (©Furrer+Frey, contact line configuration sooftware) and the 3D planning tool ELFF (©ELBAS/Furrer+Frey). Since 1999 we have SBB's mandate to maintain their design tool FACDA. Moreover, we are using other common tools such as Inventor or Microstation.

Electro-Team

Railway control systems for depots to control and supervise the switching and earthing process of the overhead contact lines in a safe manner.

Railway control systems for depots to control and supervise the switching and earthing process of the overhead contact lines in a safe manner.

Design Tools

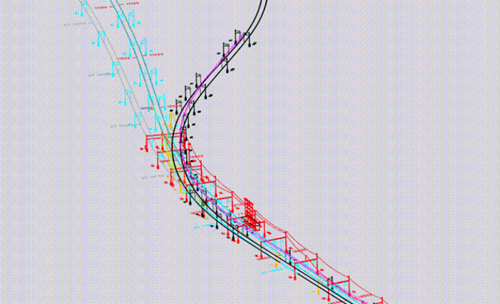

Project Design Software for Overhead Contact Line Systems

Project Design Software for Overhead Contact Line Systems

Features

- ELFF modules help users to design, build new, upgrade and maintain projects whilst saving time and keeping costs down.

- ELFF provides definitive information on technical feasibility and construction costs in the shortest possible time.

- ELFF makes it possible to design overhead contact line systems of whatever type on the basis of a 3D model, showing the tracks, the surrounding area and the overhead contact line.

- ELFF is a project design tool based on AutoCAD.

Build

Contract Management

Experienced contract managers guarantee for safety on site, on-time delivery and cost-effectiveness.

Experienced contract managers guarantee for safety on site, on-time delivery and cost-effectiveness.

Assembly and Installation

Furrer+Frey provide professional expertise in maintenance work, fault repairs, refurbishment, the construction of new systems, trained fitters, the hire of tractive power or plant.

Furrer+Frey provide professional expertise in maintenance work, fault repairs, refurbishment, the construction of new systems, trained fitters, the hire of tractive power or plant.

On-call Service

Furrer+Frey’s on-call service is available in Switzerland in case of overhead contact line failures. In general, personnel can be expected to be on site within 4 to 6 hours.

Furrer+Frey’s on-call service is available in Switzerland in case of overhead contact line failures. In general, personnel can be expected to be on site within 4 to 6 hours.

Machinery and Tools

Our factory facilities hold a great many vehicles and specialised contact line construction equipment for our customers' and our assembly teams' disposal. We have a stand-by squad for emergencies and practice preventive maintenance to ensure continuous operation of all machinery.

Our factory facilities hold a great many vehicles and specialised contact line construction equipment for our customers' and our assembly teams' disposal. We have a stand-by squad for emergencies and practice preventive maintenance to ensure continuous operation of all machinery.

The vehicles are fitted with particle filters