Jets

Visiting address

Myravegen 1

6060

Hareid

Postal address

Myravegen 1

Hareid , 6060

Contact person

Jan Tore LeikangerJoin our community for FREE today!

Create and share your own profile

Join the discussions

Publish your own items

Subscription to our Weekly eNewsletter

Get connected with Mass Transit Professionals Worldwide

FREE membership benefits

- * create and share your own profile

- * join the discussions

- * publish your own items on Mass Transit Networkmanage news, jobs, tenders, companies, events, showcases, educations, associations and literature.

- * subscribe to our eNewsletter

Company information

Sanitary Systems Made to Please

Corporation

Founded in 1986, the Jets™ group has grown steadily and today is a worldwide organisation. We offer advanced sanitary solutions with extremely low water consumption for use in land-based as well as offshore and ship sanitary systems.

The patented Vacuumarator™ pump technology is the platform of the corporation's vacuum sanitary systems. This efficient vacuum pump is the compact and water saving solution to the sanitation requirements of the future.

Technology

The continuous refinement of our product range is driven by a desire to constantly provide our customers with the best solutions available. Now, more than ever, customers require products that are also geared towards sustainability and Greentech solutions. Our water-saving systems easily comply with these requirements.

Greentech products, a steady stream of innovative solutions, and being one step ahead of the competition have been - and will continue to be - typical characteristics of Jets™.

Product news

Jets™ has a reputation for innovation, and we are known to continously develop new solutions, products and technology. Our recent achievements include the new and groundbreaking sewage treatment plant Ecomotive™ by Jets™.

Vacuum advantages

Jets™ vacuum sanitary systems have several advantages over their traditional gravity counterparts. With more than 200,000 Jets™ vacuum toilets in operation, on all continents and on the seven seas, the pleasing features of Jets™ systems are appreciated by owners and operators of ships and buildings world wide.

Vacuumarator™ pump

Our unique Vacuumarator™ pump comes in different sizes to improve the efficiency of any vacuum system, and is the most compact, efficient and reliable vacuum generator available for vacuum toilet systems. In-line installation combined with a small footprint allows unique installation flexibility and weight savings.

Other achievements

Jets™ has had several breakthroughs in vacuum sanitation technology, and we aim to come up with even better solutions in the future. Here is a selection of our achievements so far.

Research and development

Jets™ does extensive amounts of work in research and development of innovative, new and improved solutions for vacuum sanitary systems, sustainability, and various wastewater treatment technologies. We enlist the help of our business partners to assist us in developing the best technology available.

Company information

6060 Hareid

Norway

Solutions

- Sanitary

Product information

Railway

Vacuum toilets for railway rolling stock - Vacuum toilets are widely used in railway applications, and Jets™ has supplied vacuum toilets to railway operators for several years. Passenger comfort increases with Jets™.

Proven reliable performance and very limited sewage volumes make Jets™ systems the perfect choice for rolling stock, where water tanks and sewage collecting tanks have to be kept as small as possible. We have long experience in this field, and our products are highly suitable for these demanding applications.

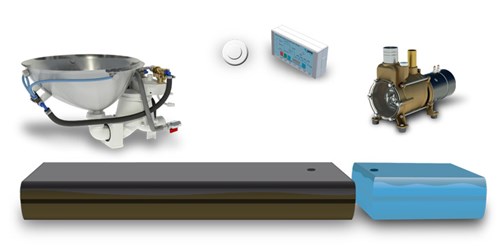

Sanpack™ plug-in module

Sanpack™ is an extremely compact solution for any railway sanitation challenge. This innovative solution is a true plug-in module that uses less than half a square metre / 5 square feet for everything needed to serve 2 toilets!

Size matters

With its simple and compact design, the Sanpack™ gives train operators the benefits of less weight, fewer parts, simpler logistics and a smaller footprint onboard the train.

Easier installation

Because the Sanpack™ is a true prebuilt plug-in module, there is less planning and project work to do. There is also less installation work. This in turn means:

- Less manpower needed

- Less need for subcontractors

- Less commissioning/testing

- Less downtime

Options

The freshwater tank can be equipped with a heater for increased passenger comfort. The Vacuumarator™ pump can also be heated in areas with risk of freezing.

The unit weighs only 140kg/300lbs!

(Weight may vary according to specifications.)

For custom installation

The compact size of a Jets™ system and its flexible piping options makes it ideal for installation in all types of rail applications. The pump can be installed separate from the toilet for easier installation. The water and collecting tanks can be installed totally independent of the pump's location.

For all types of rolling stock

In some rail cars, installing a prebuilt sanitation module like our Sanpack™ may not be an option. This is often the case with retrofits, where there is limited design flexibility because the new components must fit in a older car design.

Jets™ solution

Fortunately, our products work just as well in a customized installation. Their design and integration flexibility means they can be installed in virtually all applications.

Components available

Our modular product range means that we can supply the components needed for your specific application. If you have a sanitary challenge, we want to know about it and help you solve it.

Benefits for travellers and crews

Jets™ offers superb sanitary comfort with high-quality products that make the travelling experience more comfortable for today's demanding travellers.

Increased comfort

Products made from stainless steel or elegant porcelain combined with efficient vacuum flushing, results in a clean bowl after every flush. Automatic flushing is also available.

Hygienic and fresh

The vacuum system is completely closed. No odours or bacteria-laden aerosol from toilet flushes can escape. In addition to a vacuum valve in the toilet, a water trap ensures hygienic conditions after every flush. The Jets™ system extracts up to 80 litres / 21 gallons of air from the toilet cubicle - adding an extra level of hygiene.

Environmental benefits

The Vacuumarator™ pump grinds waste to a macerated pulp that is optimal for any sewage treatment system. The Jets™ system can already handle stricter regulations for greywater discharge.

All-in-one VOD™

With Vacuum On Demand (VOD™), the Vacuumarator™ pump generates vacuum to remove the waste in an effective all-in-one operation.

Withstands freezing temperatures

Jets™ offers a system to drain the water from the pump, as well as a heating system that keeps the pump from freezing.

Connections

24V, 36V, 72V and 110V DC power can all be used, as well as 115V and 230V AC power. A water source is the only other connection needed, making our solution a true plug-in system. There is no need for compressed air.

Jets™ provides numerous advantages for...

Manufacturers and operators will find that a Jets™ system has many advantages, and can deal with waste from both toilets and wash basins. Several units can be connected to a single Vacuumarator™ pump. The compact and flexible solutions offer great potential to designers, and are highly suitable for retrofits. Toilets for disabled people are available.

Cabin and rolling stock manufacturers

- The system can be supplied with toilets or inner bowls

- No compressed air is needed

- One module system can serve two toilets

- Compact design makes the most of the space on board

- Lightweight plastic tanks simplify design

- Toilets for disabled users are available

- Highly suitable for refurbishment projects

- Compact and flexible solutions offer great potential to designers

- Tested and approved

Railway operators

- Low maintenance and low life cycle costs

- Supreme comfort for passengers

- Highly efficient flushing

- Hygienic and odour free

- One-step operation with Vacuum On Demand (VOD™)

- Control and monitoring systems ensure stable and reliable functioning

- Low water and power consumption

- Easy to inspect, service and repair

- The Vacuumarator™ pump grinds solids to prevent clogging, and foreign objects are trapped before they get to the pump

- Proven performance at high altitudes and freezing temperatures

Buses

Buses will have great advantages and benefit greatly from using vacuum sanitary systems. We have installed our space-saving solutions in buses with very good results. Passenger comfort increases with Jets™.

Proven reliable performance and very limited sewage volumes make Jets™ systems the perfect choice for trains and buses, where sewage collecting tanks have to be kept as small as possible. We have long experience in this field, and our products are highly suitable for these demanding applications.

Benefits for passengers and driver

With their compact size and flexible piping options, Jets™ vacuum systems are ideal for installation in the confined spaces of a bus. The pump can be installed separate from the toilet, and the collecting tank can be installed totally independent of the pump's location.

Installation

Jets™ systems for buses are easy to install. Standard systems feature a toilet, a pump, a control unit and a collecting tank. A water tank and a power connection is all you need to make our systems work. Washbasins or sinks can also be connected to the vacuum system by using a greywater interface tank.

Benefits for passengers and driver

With their compact size and flexible piping options, Jets™ vacuum systems are ideal for installation in the confined spaces of a bus. The pump can be installed separate from the toilet, and the collecting tank can be installed totally independent of the pump's location.

Passenger care

Passengers want higher sanitary standards in bus restrooms, and we can't blame them. The prospect of going for a long bus drive with less than satisfactory sanitary comfort levels is not something most people look forward to. We agree that some bus restrooms are anything but enjoyable, but with a Jets™ system that changes. We use the same porcelain toilets that cruise line passengers have enjoyed for decades, and the vacuum system removes odour from the restroom with every flush.

Driver convenience

Bus drivers don't want the hassle of emptying the sewage collecting tank at frequent intervals, so on shorter drives it is not uncommon for bus restrooms to be locked and unavailable for use. We can't blame the drivers either, because without a Jets™ system it's not a very pleasant job to empty the collecting tank. With a Jets™ system however, the emptying intervals are long and the sewage has been turned into a finely macerated pulp before being pumped into the tank.

Greywater collection

Water from sinks (and showers) can be connected to the vacuum system by using a Jets™ greywater interface tank. Self-contained and equipped with an automated emptying valve, the interface tank will move greywater to the collecting tank along with other sewage.