The Paris-Bordeaux high speed line was inaugurated on 2 July 2017. Introduced in 1992, it took more than 25 years for this project to become a reality. APS took part in 2 crucial points of this new high speed line, firstly by providing an automated noise barrier precast plant to Bonna Sabla, then by providing sleeper moulds to Stradal.

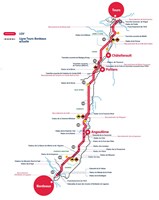

In 1992, the project linking Paris to Bordeaux in 2 hours with a high speed line was started. However, it took 20 years for the construction to begin. In 2012, CBE Group’s department, APS, only just created at the time, provided a noise barrier carousel to Bonna Sabla. These noise barriers would reduce noises made by trains, which could disturb the inhabitants of the 117 towns crossed by the high speed line.

An automated plant for noise barriers is quite uncommon. APS had to design a very specific plant that could handle the use of 30 moulds (of 2 different types) constantly turning in the plant, allowing a productivity of 40 walls every 8 hours, with an average cycle time of 21 minutes.

In 2015, APS provided pre-stressed concrete sleeper moulds to Stradal, as well as the necessary equipment for the production.

The Paris-Bordeaux line is part of a larger railway construction project of more than 2,000km for a cost of 7,8 billion euros, project that should be completed by 2020. According to estimations, 20 million passengers are expected per year, 3 million more than before.

About Advance Precast Systems (APS)

APS - Advanced Precast Systems designs, manufactures and assembles complete turnkey factories for the production of concrete elements for rail track construction such as sleepers and slabs. The innovative precast approach of APS offers you a significant advantage: increasing your productivity by improving work safety, reducing workforce, time and space.

For more than 25 years now, our customers trust in our experience in designing and manufacturing high quality moulds, equipment and precast facilities worldwide. Directly linked to CBE Group, the mother company world leader in moulds and precast facilities for tunnel segments.

Comments

There are no comments yet for this item

Join the discussion