Technology

The application of leading-edge technology, fast and safe development of our future products, including the achievement of their excellent quality, represent a logical step for the further advancement of research and development across the whole company.

Škoda Transportation focuses on the improvement and prediction of critical properties for future products, such as noise resistance, safety of traction drives, electromagnetic and thermal calculations and the subsequent optimization of engines. The results of the research are products with pivoting bogies which have low-energy electric drives of wheels reducing thus the maintenance costs of vehicles and infrastructure.

Škoda Transportation focuses on the improvement and prediction of critical properties for future products, such as noise resistance, safety of traction drives, electromagnetic and thermal calculations and the subsequent optimization of engines. The results of the research are products with pivoting bogies which have low-energy electric drives of wheels reducing thus the maintenance costs of vehicles and infrastructure.

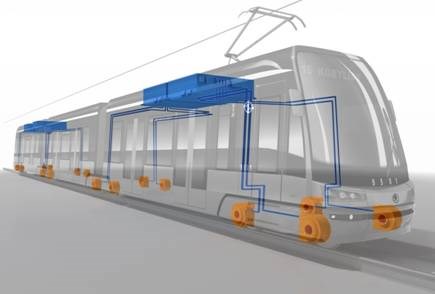

In 2009 a brand-new technology workplace for the development of synchronous motors with permanent magnets - which are a vital part of the traction drive of the ForCity Alfa tram - was completed. These motors are world leaders and enable the construction of low-bed pivoting bogies with a direct drive (without a gearbox). Owing to the size of this machine and the requirements of the moment the development was very complicated and lasted three years. Each traction motor is individually controlled from its own inverter, and this allows to control the moments individually for each wheel. Each traction container is designed for one traction bogie and represents the total utilization of the current high-performance electronics. By means of quick communication it is possible to optimize passes through the curve and achieve higher safety when driving through the curve.

In 2009 a brand-new technology workplace for the development of synchronous motors with permanent magnets - which are a vital part of the traction drive of the ForCity Alfa tram - was completed. These motors are world leaders and enable the construction of low-bed pivoting bogies with a direct drive (without a gearbox). Owing to the size of this machine and the requirements of the moment the development was very complicated and lasted three years. Each traction motor is individually controlled from its own inverter, and this allows to control the moments individually for each wheel. Each traction container is designed for one traction bogie and represents the total utilization of the current high-performance electronics. By means of quick communication it is possible to optimize passes through the curve and achieve higher safety when driving through the curve.

One of the most demanding applications of high-performance traction engines are diesel-electric mining vehicles. Customers require from them extraordinary reliability and robustness of the engine. Successful development of this engine for the American company Caterpillar allowed us to obtain the prestigious award for the best supplier of the Caterpillar company in 2011. These are machines with absolutely unique design which are able to work in extremely difficult conditions.

One of the most demanding applications of high-performance traction engines are diesel-electric mining vehicles. Customers require from them extraordinary reliability and robustness of the engine. Successful development of this engine for the American company Caterpillar allowed us to obtain the prestigious award for the best supplier of the Caterpillar company in 2011. These are machines with absolutely unique design which are able to work in extremely difficult conditions.

A series of technologically innovative products is gradually coming into serial production. The main innovations in this direction include a traction drive for a three-system Emil Zátopek locomotive which places extraordinary demands on power electronics. Traction converters must adapt to the three power systems. The most difficult part of the research concerned electromagnetic compatibility and the suppression of interference of the railway interlocking system in all countries where this vehicle will be operated.

The development also focuses on enhancing effective utilization of applied materials. This applies, for example,to non-traditional materials, such as fiber composites or aluminium alloys. Advanced technologies also include laser welding, a higher use of extracts and castings thanks to the latest production methods or improved methods of material bonding. These approaches deliver primarily lower weight of vehicles which leads in its turn to more efficient transport from the point of view of energy consumption.

The development also focuses on enhancing effective utilization of applied materials. This applies, for example,to non-traditional materials, such as fiber composites or aluminium alloys. Advanced technologies also include laser welding, a higher use of extracts and castings thanks to the latest production methods or improved methods of material bonding. These approaches deliver primarily lower weight of vehicles which leads in its turn to more efficient transport from the point of view of energy consumption.

Investments are also made in the equipment of technical laboratories which enables improving the effectiveness of the work process. Purchase of specialized software solutions used mainly for simulations which are demanding on the hardware and the expertise of people is natural for us. Testing by means of simulation is used primarily as a tool for reducing development costs and the necessary time. Without the simulations new approaches would have to be checked out on the finished vehicle.

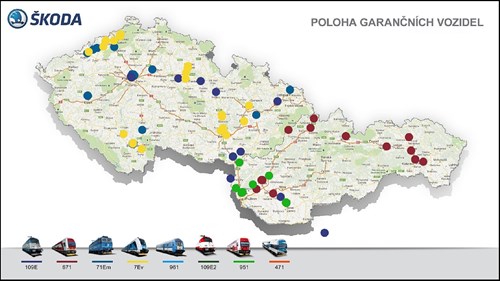

The Škoda company has developed its own online system of tracking locomotives and electric units in operation. It is sophisticated online tracking of all vehicles which are currently operated. The technicians have at their disposal a detailed map showing the location of every train, which maintains contact with the control room and which regularly sends information about its precise location, current speed, travelled kilometres and technical condition. This permanent monitoring provides not only a clear overview of the movement and use of individual products in the field, but above all it sends information about possible faults and deficiencies. As soon as a fault occurs, exact information is sent immediately to the control room and the technicians therefore know which particular vehicle is encountering a problem and they can prepare for its repair in advance.

The Škoda company has developed its own online system of tracking locomotives and electric units in operation. It is sophisticated online tracking of all vehicles which are currently operated. The technicians have at their disposal a detailed map showing the location of every train, which maintains contact with the control room and which regularly sends information about its precise location, current speed, travelled kilometres and technical condition. This permanent monitoring provides not only a clear overview of the movement and use of individual products in the field, but above all it sends information about possible faults and deficiencies. As soon as a fault occurs, exact information is sent immediately to the control room and the technicians therefore know which particular vehicle is encountering a problem and they can prepare for its repair in advance.

Comments

There are no comments yet for this item

Join the discussion