China CNR Corporation Ltd.

Visiting address

Fangcheng Park, First Area, No.15

100078

Beijing

Postal address

Fangcheng Park, First Area, No.15

Beijing , 100078

Contact person

Xi GuohuaJoin our community for FREE today!

Create and share your own profile

Join the discussions

Publish your own items

Subscription to our Weekly eNewsletter

Get connected with Mass Transit Professionals Worldwide

FREE membership benefits

- * create and share your own profile

- * join the discussions

- * publish your own items on Mass Transit Networkmanage news, jobs, tenders, companies, events, showcases, educations, associations and literature.

- * subscribe to our eNewsletter

Company information

Leading Solution in Rolling Stock

CNR is the largest world leading manufacturer & solutions provider of rolling stock. Revenue in 2012 is RMB 92.4 billion, which continue to hold No. 1 in world rolling stock industry.

CNR is mainly engaged in design, manufacture, refurbishment, service and lease of rolling stock. Headquartered in Beijing, CNR has 86,138 employees divided among over 20 subsidiaries and has world advanced technology platform of high-speed EMUs, high power locomotives, heavy load wagons, coaches, metros and urban rail vehicles as well as world leading manufacturing ability. The annual output of CNR is 1,000 electric locomotives and diesel locomotives, 4,000 multiple-unit train-sets, passenger coaches and urban railway vehicles, 30,000 freight wagons, which share over half of the market in China, and are exported to over 80 countries and regions.

CNR consists of a great number of technological talents with expertise in locomotives, rolling stocks and other products. The soul of CNR enterprise is innovation in technology in its course of development. CNR is actively engaged in the construction of "the national engineering laboratory of high-speed train system integration", "the national key laboratory of traction and control of EMU & locomotive", “the national engineering technology research center of system integration of rail coach”, “the national engineering technology research center of heavy load & rapid freight wagon”, and other national level R&D platforms. CNR continues to lead the technology development of Chinese rolling stock. CNR has 8 national level enterprise R&D centers, 5 postdoctoral workstations and 4 academician expert workstations.

CNR has always been internationally reputed for its high quality. All production enterprises have registered with the ISO9001, ISO14001 and OHSAS18001 certification. Most have registered with IRIS certification. Some have acquired certificates from AAR and TSI.

CNR has strong ability in machining, casting, forging, steel fabricating, welding and assembling as well as in developing motor and electrical equipments. Highly competent employees, high technical product examination and efficient management system are the guarantee of high quality products.

The focus of CNR is quality. It is the way we do business. Our policy is to strengthen the management to serve the market and, therefore, to supply products conforming to international standards and/or customers. Every product receives the strict scrutiny from the first operation to the last. Operators, inspectors, supervisors, and managers assure that the products our customers receive meet quality standards.

CNR produces a family of AC propulsion electric locomotives with high tractive power capable of drawing more than 5,000 tons with a single locomotive. CNR manufactures 10,000 kW electric locomotives, the most powerful ones in the world.

CNR develops and manufactures modern mass transit vehicles which offer low-level access, clear view, low noise and comfort. Design feature include bolsterless bogie, aluminum floor, automatic drive, driverless system and VVVF propulsion. CNR products relieved the crowdedness of traffic in large cities.

CNR manufactures a full line of freight wagons with axle load up to 40 tons, including covered wagons; open-top wagons for coal, ore, steel and timber; hopper wagons for grain, ore, fertilizer; flat wagons; double-deck container flat wagons; tank wagons for all types of liquid and chemicals; tipper wagons, as well as schnabel and depressed center wagons. Designed for economical loading and unloading, CNR’s innovative freight wagons offer operators and customers the advantages of great loading capacity and simple handling.

CNR is committed to working in close partnership with its users to ensure long-term success of the rolling stock – in safety, in reliability, in environmental protection, in customer service and in cost-effectiveness.

Company information

100078 Beijing

People's Republic of China

100078 Beijing

People's Republic of China

Solutions

- Railbound Vehicles for Public Transport

Product information

Rolling Stock

Electric Locomotives

CNR produces a family of AC propulsion electric locomotives with high tractive power capable of drawing more than 5,000 tons with a single locomotive. CNR manufactures 10,000 kW electric locomotives, the most powerful ones in the world.

CNR produces a family of AC propulsion electric locomotives with high tractive power capable of drawing more than 5,000 tons with a single locomotive. CNR manufactures 10,000 kW electric locomotives, the most powerful ones in the world.

The HX series is a new AC drive electric locomotive for freight traffic, which including HXD2 family and HXD3 family. The 7,200 KW and 10,000 kW locomotives feature high tractive power capability for drawing over 5,000 tons with a single locomotive. The HXD2 electric locomotives with 10,000 kW featured good performance in hauling 20,000 tons coal train on Datong-Qinhuangdao line on 16 January 2008. The modified 9,600 kW locomotive БКГ-1 AC are made for Belarus.

The SS range of electric locomotives features microprocessor control and anti-slip braking. The SS4G and SS3B eight-axle double units are suitable for heavy haul freight service; The SS7 series is used for high-speed passenger service. The SS7E is the modular mass transit solution which addresses the need for high speeds.

- Type БКГ-1 Electric Loco. for Belarus

- Type HXD2B Electric Locomotive

- Type HXD2 Electric Locomotive

- Type HXD2C Electric Locomotive

- Type HXD3 Electric Locomotive

- Type HXD3B Electric Locomotive

- Type SS7E Electric Locomotive

Diesel Locomotives

CNR designs and manufactures a wide range of railway freight and passenger diesel locomotives based on its own intellectual property. Flexible and economical, these locomotives embody decades of experiences and expertise in manufacturing. Based on proven design and engineering standards, they can easily be tailored to individual customer needs. CNR manufactures 4,660 kW diesel locomotives, the most powerful ones of its kind in the world.

CNR designs and manufactures a wide range of railway freight and passenger diesel locomotives based on its own intellectual property. Flexible and economical, these locomotives embody decades of experiences and expertise in manufacturing. Based on proven design and engineering standards, they can easily be tailored to individual customer needs. CNR manufactures 4,660 kW diesel locomotives, the most powerful ones of its kind in the world.

The HX range of diesel-electric locomotives is a result of cooperation with EMD. The 4,660 KW locomotives feature high tractive power capability for freight traffic.

The DF range of diesel-electric locomotives, with a four-stroke turbocharged diesel engine and AC/DC transmission, are the main types of main line locomotive for both passenger and freight traffic. They run on three-axle bogies with roller bearings. The traction motors are fully suspended with hollow shaft quill drive.

Types DF4D, DF8B are designed for heavy-duty freight trains. Types DF4D, DF10F and DF11 for high-speed passenger service and Types DF5 and DF7 for shunting work. Type DF4DJ is equipped with AC traction equipment and IGBT converters.

The GK range of diesel locomotives are intended for shunting and industrial applications. Many have hydraulic transmission and have a B-B configuration to suit tight curves.

The CK series diesel locomotives are designed for markets other than China and feature a lower axle load; examples are in operation on the narrow-gauge or broad-gauge railways of Argentina, Angola, Congo (B), Congo (K), Cuba , Estonia , India, Iran, Iraq, Libya, Malaysia, Mongolia, Myanmar, New Zealand, Korea , Nigeria, Pakistan, Saudi Arabia, Sierra Leone, Liberia, Tanzania, Turkey and Vietnam.

- Type DF7G-E Diesel Loco. for Estonia

- Type CKD4B Diesel Loco. for Mongolia

- Type CKD6B Diesel Loco. for India

- Type DF10DDB Diesel Loco. for Saudi Arabia

- Type CKD8E Diesel Loco. for Malaysia

- Type DF7G-C Diesel Loco. for Cuba

- Type CK1E Diesel Loco. for Vietnam

- Type CK6E Diesel Loco. for Congo (B) & Angola

- Type CK6E1 Diesel Loco. for Angola

- Type CKD7C Diesel Loco. for Congo (K)

- Type CKD0 Diesel Locomotive for Turkey

- Type CKD7 Diesel Loco. for Myanmar

- Type CKD8A Diesel Loco. for Nigeria

- Type CKD8B Diesel Loco. for Tanzania

- Type CKD9B Diesel Loco. for New Zealand

- Type CKD9 Diesel Loco. for Pakistan

- Type DF4D Diesel Loco. for Iran

- Type DF10FI Diesel Loco. for Iraq

- Type CKD4A Diesel Loco. for North Korea

- Type DF4D Diesel-electric Locomotive

High Speed Trains

CNR has developed high-speed trains of speed at 200 km/h and over 300 km/h in order to meet the demand of high-speed intercity transportation service. With high capacity, comfortable sitting, cutting edge technology, high reliability, long intervals between overhauls and long life time, CNR products represent the future of high-speed trains.

CNR has developed high-speed trains of speed at 200 km/h and over 300 km/h in order to meet the demand of high-speed intercity transportation service. With high capacity, comfortable sitting, cutting edge technology, high reliability, long intervals between overhauls and long life time, CNR products represent the future of high-speed trains.

- CRH380BL 380km/h High Speed Train

- CRH380CL 380km/h High Speed Train

- CRH3 350 km/h High Speed Train

- CRH5 250 km/h EMU with distributed power

Multiple Units

CNR offers its customers the solution aimed to maximize their mobility. With optimized carbody and bogie design of reduced weight and enhanced strength, the multiple-unit train provides superior reliability and comfortable sitting.

CNR offers its customers the solution aimed to maximize their mobility. With optimized carbody and bogie design of reduced weight and enhanced strength, the multiple-unit train provides superior reliability and comfortable sitting.

- EMU for Brazil

- Type KZD2 "Chuncheng" EMU for Kunming

- DMU for Ghana

- Type NZJ2 "Shenzhou" Double-deck DMU

- Type SYZ25 "Lushan" Double-deck DMU

- "Jinlun" Double-deck DMU

Metro Cars

CNR metro cars adopt lightweight carbody made of stainless steel and aluminum, Automatic Train Supervision System (ATS) and Automatic Train Protection System (ATP). They feature high reliability, availability, less maintenance and low life time cost. Delivering type A metro cars to Hong Kong MTR and Saudi Arabia marks CNR’s entrance into the high-end international markets.

CNR metro cars adopt lightweight carbody made of stainless steel and aluminum, Automatic Train Supervision System (ATS) and Automatic Train Protection System (ATP). They feature high reliability, availability, less maintenance and low life time cost. Delivering type A metro cars to Hong Kong MTR and Saudi Arabia marks CNR’s entrance into the high-end international markets.

- Metro Cars for Hong Kong

- Metro Cars for Saudi Arabia

- Metro car for Argentina

- Metro car for Brazil

- Metro Cars for Thailand

- Metro Cars for Line 1 of Tehran

- Metro Car for Line 10 of Beijing Subway

- Metro Car for Line 5 of Beijing Subway

- Metro Car for Line 2 of Beijing Subway

- Metro Car for Tianjin

- Metro Car for Line 2 of Tianjin

- Metro Car for Shanghai Line 1

- Metro Car for Shenyang

- Metro Car for Line 2 of Xi'an

- Metro Car for Guangzhou

- Metro Car for Shenzhen

- Metro Car for Guangzhou-Foshan Line

Mass Transit Vehicles

CNR develops and manufactures modern mass transit vehicles which offer low-level access, clear view, low noise and comfort. Design feature include bolsterless bogie, aluminum floor, automatic drive, driverless system and VVVF propulsion. CNR products relieved the crowdedness of traffic in large cities.

CNR develops and manufactures modern mass transit vehicles which offer low-level access, clear view, low noise and comfort. Design feature include bolsterless bogie, aluminum floor, automatic drive, driverless system and VVVF propulsion. CNR products relieved the crowdedness of traffic in large cities.

- LRV for Mashhad, Iran

- Linear-motored Train for Beijing Airport

- 100%Low Floor LRV with Aluminum-bodied

- 100%Low Floor Tram

- Low Floor LRV for Changchun

- Type DL6W LRV for Dalian

- Type QKZ2 Monorail Car for Chongqing

- Medium-low Speed Maglev Car

- Type DKZ6 Commuter Train for Beijing

- Rapid Trainset Vehicle for Tianjin

- mmuter Train for Wuhan

- Type FG AC Drive LRV for Dalian

Coaches

Safety, reliability, speed and comfort are the top priority for passenger coaches. For over 60 years, CNR has concentrated its effort on the development of high quality and environmentally friendly coaches. Currently, thousands of quality products equipped with non-flammable interior material, compact vacuum toilets, automatic train supervision system (ATS) has been supplied to MOR and customers around the world.

Safety, reliability, speed and comfort are the top priority for passenger coaches. For over 60 years, CNR has concentrated its effort on the development of high quality and environmentally friendly coaches. Currently, thousands of quality products equipped with non-flammable interior material, compact vacuum toilets, automatic train supervision system (ATS) has been supplied to MOR and customers around the world.

- Double Deck Coaches for Australia

- Double Deck Coaches for Iran

- Coaches for Kazakhstan

- Coaches for Turkmenistan

- Coaches for Mongolia

- Coaches for Bangladesh

- Coaches for Sri Lanka

- Coaches for Pakistan

- Type 25T Passenger Coach

- Type 25K Passenger Coach

- Type 25G Passenger Coach

Components

CNR serve rail component market through its activities in the fields of diesel engine, motor, locomotive, coach, wagon, forgings and castings. Our expertise lies in designing and manufacturing a comprehensive range of components, while we maintaining good quality, reasonable price and quick turnarounds. We can provide a cost-effective and timely solution to parts or components that are mechanical or electrical, moulded, forged or finished, metal or non-metal.

We maintain a close working relationship with every customer - from design to delivery - to assure that their performance needs are met, no matter the crankshaft is slated for a high performance locomotive or a hard working wheel-set performing critical duty. We adopt professional assistance with CAD/CAM to process a variety components suited to customer’s needs and peculiarities. If customers provide us with drawings, samples, or materials, our engineering and product development department will then enhance the work to maximize quality and effectiveness.

Motors

We are a leading supplier of manufacturing traction motors and generators for locomotive, urban rail vehicle, oil drilling machine, mining machinery, metallurgical machinery and wind-driven generator.

We are a leading supplier of manufacturing traction motors and generators for locomotive, urban rail vehicle, oil drilling machine, mining machinery, metallurgical machinery and wind-driven generator.

Our traction motors have been developed by the latest findings in electromagnetic design, construction, insulation and ventilation engineering and of the abundance of experience in manufacturing direct current machines. At the same time, the desire of our customers for low maintenance expense and high reliability as well as long life has been taken into account.

Our products have been exported to worldwide like USA, Canada, Egypt Switzerland and Russia. We can also repair and improve the existing traction motors and generators according to the customer’s requirements. We offer the customer a high value and cost effective motor or generator.

- Type TQFR-3000E Synchronous Main Alternator

- Type JF204D Synchronous Main Alternator

- Type ZD109D DC Traction Motor

- Type ZD106A DC Traction Motor

- Rotating for DF11G Diesel Loco.

- Pulsating Current Traction Motors

- Type JGL405F Exciter

- Type ZQF-80 Dynastarter

- Type JQF409S Synchronous Dynastarter

- Type ZQDR-310 DC Traction Motor

- Type YZ141B Traction Motor

- Type ZD111 Pulsating Current Traction Motor

- Type YJ105A Asynchronous Traction Motor

- Type YJ90 Asynchronous Generator

- Type YJ85A AC Traction Motor

- Type YJ92A Asynchronous Traction Motor

- Type YJ87A Asynchronous Traction Motor

- Type YZ22 DC Traction Motor

- Type JD115 Asynchronous Traction Motor

- Type YZ08F DC Drill Motor

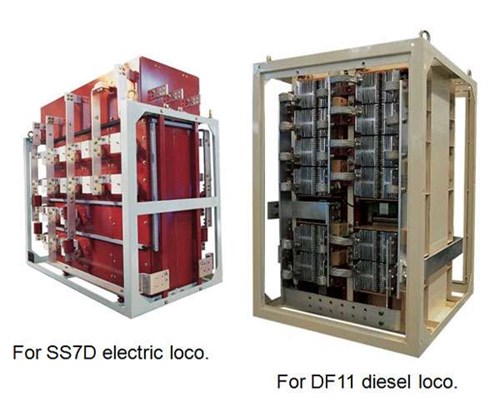

Electric Control Equipment

Electric Control Equipment

CNR offers customers electric control equipment for electric locomotive, diesel locomotives, coaches, metro cars, etc, which include locomotive power rectifier panel, converter and inverters, network control products, traction and control integration products, passenger-related information technology, high power rectifier diodes and thysistors, contractor, etc.

Design capabilities and software include AutoCAD and Finite Element Analysis. Generally, customers provide us with initial drawings of the desired products, our engineering and development department will then enhance the design to maximize quality and effectiveness.

We have a history of maintaining excellent relations with customers based on quality and performance. Yet, we are developing even closer customer relations and taking role in the total supply and manufacturing. We are accessible to all customers and invite all customers current and potential to visit our current systems and production.

- Locomotive Power Rectifier Panel

- Metro Control Equipment

- 2Q213 traction and auxiliary converter for CRH5 ...

- Converter and Inverters

- Power Device Compartment

- Control Equipment

- 1700kVA Traction Inverter

- Master Operation Desks

- Rectifier Diodes and Thysistors

- Contractors

- Power/Electronic Products

- Electropneumatic Brake System

- HXD2B Electric Loco. Control & Monitoring System

- Braking System for Metro

- ACU Main Plate

Locomotive Components

We offer customers a complete range of locomotive components, systems, and services covering design and manufacture of diesel engines, motors, air compressors, turbochargers, water pumps, oil pumps and power/electric products, as well as other products while maintaining good quality, reasonable price and short delivery time.

We offer customers a complete range of locomotive components, systems, and services covering design and manufacture of diesel engines, motors, air compressors, turbochargers, water pumps, oil pumps and power/electric products, as well as other products while maintaining good quality, reasonable price and short delivery time.

- Type 16V240ZJE Diesel Engine

- Type 16V240ZJD Diesel Engine

- Type 12V280ZJ Diesel Engine

- Type 12V240ZJ6E Diesel Engine

- Type GM16V265H Diesel Engine

- Type 16RK215T Diesel Engine

- Type DH Hydraulic Changeover Transmission

- Type YB480 Hydraulic Converter

- Type YB530 Hydraulic Converter

- YOT700FV Speed Regulated Hydraulic Coupler Trans...

- YO750 Hydraulic Coupler Transmission Device

- YO750 Speed Regulated Hydraulic Coupler Transmis...

- Type YB900 Hydraulic Converter

- Hydraulic Transmission Box

- Type NSG177 Screw Air Compressor

- TypeNSG242(S) Screw Air Compressor

- Screw Air Compressor

- Screw Air Compressor

- Screw Air Compressor

- Screw Air Compressor

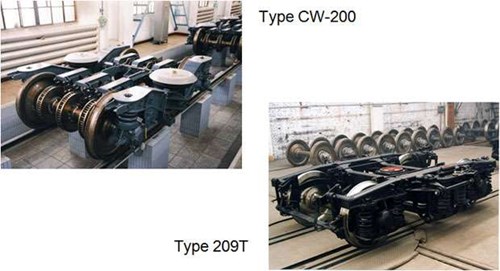

Vehicle Components

CNR serves the component market through its activities in the fields of bogies, air springs, tight-lock couplers, draft gears, brake equipment. Our expertise lie in the design and manufacture of a comprehensive range of components while maintaining good quality, reasonable price and quick turnarounds.

CNR serves the component market through its activities in the fields of bogies, air springs, tight-lock couplers, draft gears, brake equipment. Our expertise lie in the design and manufacture of a comprehensive range of components while maintaining good quality, reasonable price and quick turnarounds.

- Coach Bogies

- Wagon Bogies

- Wagon Bogies for Vietnam

- Wagon Bogies for India

- 160 km/h Wagon Bogies

- Wagon Bogies

- Wagon Bogies

- Wagon Bogies

- Bogie Parts

- Couplers

- Tight-Lock Couplers

- Air Springs

- Dampers

- Elastomeric Buffers

- Draft Gears

- Distributing Valves

- Brake Equipment

- Cooling Equipment of Power Van

- Air Dryers

- Type JBY-80 Pressurized Flush Toilet System

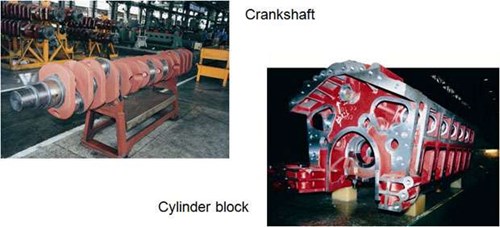

Casting & Forging

CNR can offer “One Stop Shop” service for custom ferrous and non-ferrous open die, closed die, rolled ring and extruded forgings. We know metal and how to best produce it for highly specialized applications. We can provide a cost-effective and timely solution for forge bars, rings, hubs, blank, step-down shafts, or spindles, hollows, torch cut contours, or custom-shaped parts. High strength, long life parts optimized in terms of both mechanical properties and structural integrity are, today, produced in sizes ranging from a few pounds to tons in weight. Some commonly forged part applications for railcars include high quality crankshafts, connecting rods, pistons, water jackets, gears, couplings, cardan shafts, flanges and hubs.

CNR can offer “One Stop Shop” service for custom ferrous and non-ferrous open die, closed die, rolled ring and extruded forgings. We know metal and how to best produce it for highly specialized applications. We can provide a cost-effective and timely solution for forge bars, rings, hubs, blank, step-down shafts, or spindles, hollows, torch cut contours, or custom-shaped parts. High strength, long life parts optimized in terms of both mechanical properties and structural integrity are, today, produced in sizes ranging from a few pounds to tons in weight. Some commonly forged part applications for railcars include high quality crankshafts, connecting rods, pistons, water jackets, gears, couplings, cardan shafts, flanges and hubs.

CNR manufacture highly engineered metal castings for a variety of products, including engines, motors, locomotives, passenger coaches and freight wagons. We have the ability to produce castings from a wide selection of materials, including carbon, low-alloy, high-alloy and stainless steel, gray, ductile, nodular, alloy and non-ferrous alloy iron, aluminum, zinc and copper, and the ability to manufacture parts in a variety of sizes, ranging from small die cast components for piston ring weighting a few ounces to large steel castings weighting up to 32 tons.

Combining over 100 years of metal casting knowledge with the finest materials, latest technology and best quality, we have strong capability to deliver worldwide. We currently export to Europe, USA, Japan, Korea and India conforming to international standards and/or customers’ specifications.

With the annual production capacity of nearly 130,000 tons of steel castings, 40,000 ton of iron castings and 4,000 tons of non-ferrous metal castings, we offer professional assistance with a new casting design or modification to customer’s existing parts. For customer’s special requirements, we are available for in-time assistance and door-to-door service. Our ultimate goal is to provide our customers with the best service and high quality at a competitive price. We stress partnerships with our clients and make efforts to create the example of win-win relationships, where everyone wins!

- Ductile Iron Castings

- Worm Iron Casting Cylinder Heads

- Housing Castings

- Aluminum Castings

- Investment Castings

- Steel Casting Wheels

- Brake Shoe and Wedges

- Diesel Engine Forging Parts

- Forgings

- Forgings

- Springs